Two Months and Two Grand so the Missus Could Fetch the Firewood

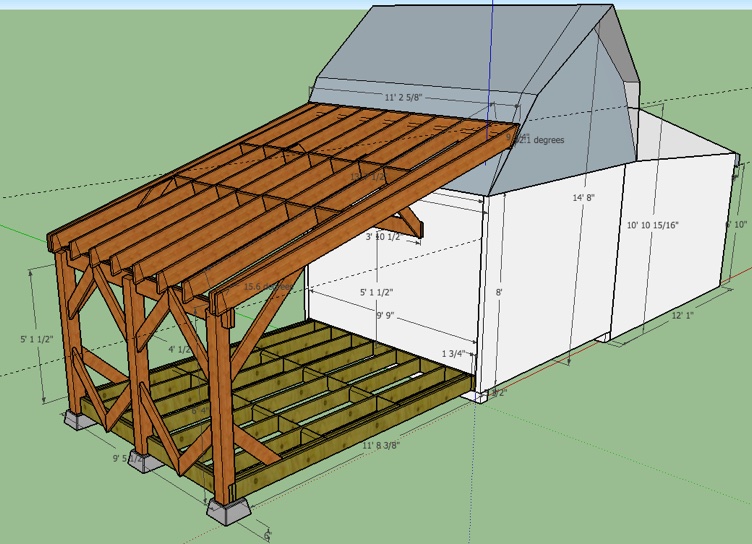

Actually, three sheds fused into one; no two of which agree on plumb or level.

A wood shed is a standard feature of most properties in the Yukon. Absent one ourselves, we took to throwing plastic sheeting over each year's firewood pile. Combined with my just-in-time-splitting policy, that made for poor, steamy burning. It also made for a grumpy wood-splitter since I was the only one who could swing the big axe.

So, after many months of idle thought, I sat down this summer and sketched a rough plan on the back of a convenient FINAL NOTICE envelope. The design is based upon the sole lesson I retained from a civil engineering course: put a triangle wherever it might fall over.

Nothing more than a floor, a roof, and three gravity repulsion units (or "posts", if you prefer, Your Majesty).

Construction took about ten days, sprinkled over two Robaxacet-fueled months.

This animation contains a few cheeky door flashings that may be upsetting to some viewers.

As usual, the sub-contractor required constant supervision.

Now that's what I call a "joist hanger."

Just dealing with all of the wood meant building lumber racks out back.

Imagine all of the possible future projects that won't be built with this lumber.

Shingling will have to wait until the spring, so I wrapped the roof in a festive blue tarpaulin for the winter. I guess we'll finally have to put a proper duvet over the bed.

All told, there's about $1200 worth of lumber, $500 worth of fasteners---mostly wrong bits that I'm sure will prove useful someday soon---and then there will still be more needed for asphalt shingles.

Most Useful Tools

- Irwin spreader clamp

- the other Irwin spreader clamp

- Corded and cordless power drills

- Reciprocating saw

- Compound mitre saw

Sadly, I didn't get to use my table saw much. My fingers are all intact though, so, you know, "glass half full."

Most Useless Tools

- The off-brand rolling lumber support that broke in two places almost immediately. I would've returned it but it somehow broke into many more unrecognizable pieces shortly thereafter.

- The Mastercraft™ spreader clamp that stopped spreading and clamping.

- The Mark's Dakota construction gloves that unravelled after only two months of casual---though incompetent---carpentry.

Items Broke

- Tape measure (always have a spare)

- Countersinking drill bit

- Maybe the belt sander...again

- Almost the circular saw, but the wobble was just an overheated dull blade

- Aforementioned useless tools

Lessons Learned

- When your best carpentry precision is only about an eighth of an inch, don't bother measuring to the sixteenth. (I tell myself that I'm at least as good as the kerf of my big saw.)

- I had a lot of trouble making the birdsmouth cuts in the rafters. But after looking it up today, I found an easy and accurate technique. Hindsight, am I right?

- Swiss-cheesing a pressure-treated plywood floor so that it will drain water is a lot more time consuming than you'd imagine. I'd have preferred expanded steel, but it was a bit too spendy.

- And this applies to pretty much anything: only the builder sees the minor mistakes.

It's Chilkoot Time!

Comments